A whip sock, also known as a cable sock, is the ideal safety device for a pressurized hose. Given the versatile applications of high-pressure industrial hoses across mining, drilling, and hydraulic-based and pneumatic–based industries, it is pivotal to secure the equipment being used to prevent accidents or injury at the facility.

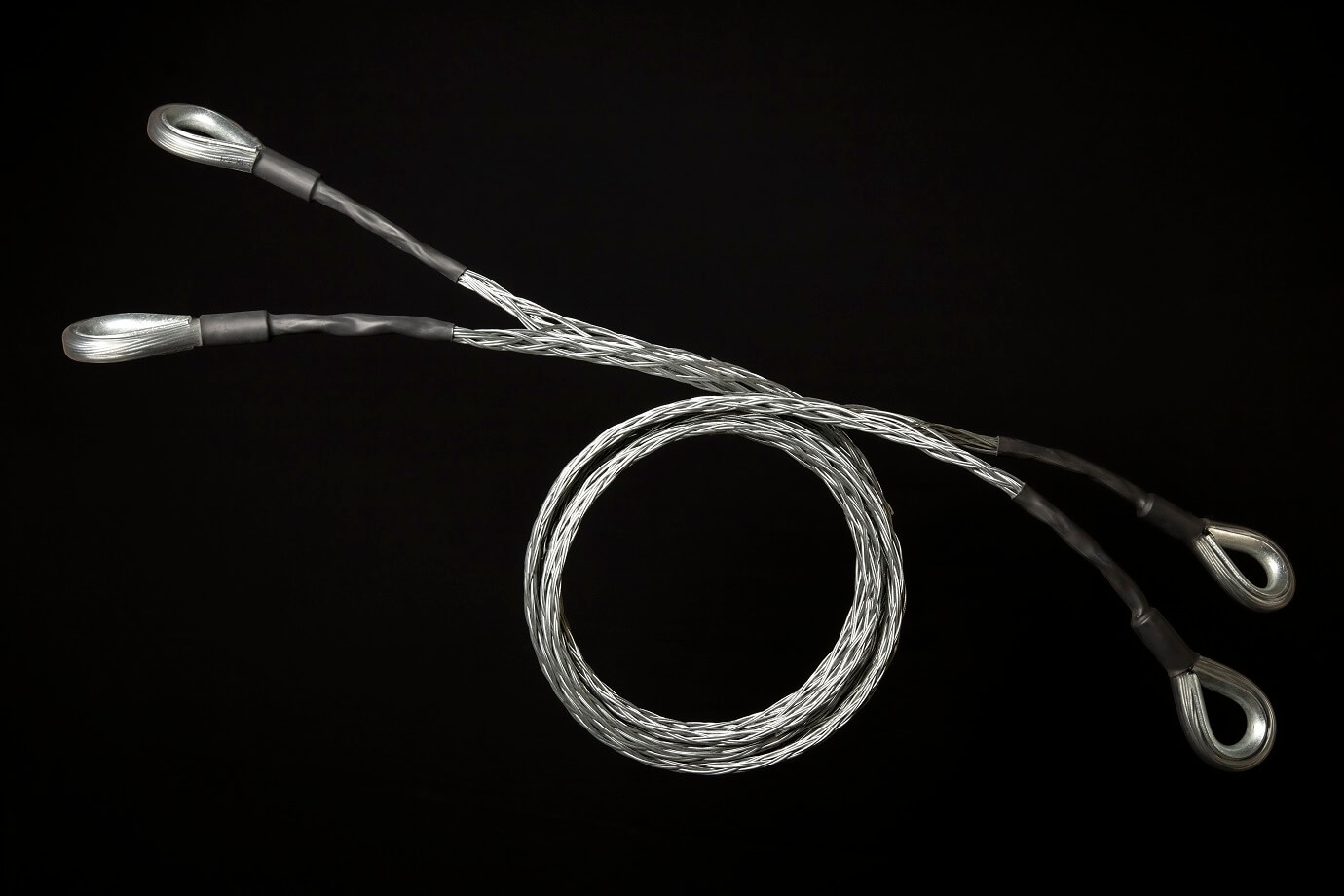

A single whip sock is essentially a hand-woven steel grip closely resembling the structure of human DNA and made using high-quality stainless steel and galvanized wire. This design supports the hose more securely over a larger area, regardless of its size.

Oftentimes, an increase in the pressure of liquid or gas through the hose can generate so much force that it ruptures the fitting and the hose in one fell swoop. This is called whipping and can be dangerous given the unpredictable nature of a heavy-duty hose when exposed to a great force. The unique build of a whip sock, in addition to its composition, makes it a highly durable product in such circumstances. If whipping occurs, the whip sock can provide the hose with the required support and stability, thus preventing damage to the equipment or potential injury to workers. While attaching a whip sock to a hose and subsequently to the source, ensure that both mounting points are engaged, and the cable grip is fully expanded across the body of the hose. It is essential that this arrangement is checked each time before using the hose, to safeguard against any problems that may arise.

| CABLE SUPPORT GRIPS | ||||||

|---|---|---|---|---|---|---|

| WHIPSOCKS | ||||||

| Part No | Cable diameter | Safe Working Load (SF:3) | Mesh length | Total length | ||

| inches | lbs | inches | in inches | |||

| HWK10 | 0.23 – 0.39 | 535 | 23.622 | 31.496 | ||

| HWK15 | 0.39 – 0.59 | 1330 | 23.622 | 31.496 | ||

| HWK20 | 0.59 – 0.78 | 1330 | 23.622 | 31.496 | ||

| HWK25 | 0.78 – 0.98 | 1670 | 23.622 | 31.496 | ||

| HWK30 | 0.98 – 1.18 | 2000 | 39.37 | 47.244 | ||

| HWK40 | 1.18 – 1.57 | 3175 | 49.213 | 57.087 | ||

| HWK50 | 1.57 – 1.96 | 3640 | 49.213 | 57.087 | ||

| HWK60 | 1.96 – 2.36 | 8575 | 59.055 | 70.866 | ||

| HWK70 | 2.36 – 2.75 | 8575 | 59.055 | 70.866 | ||

| HWK90 | 2.75 – 3.54 | 9640 | 59.055 | 70.866 | ||

| HWK110 | 3.54 – 4.33 | 10730 | 59.055 | 72.835 | ||

| HWK130 | 4.33 – 5.11 | 11800 | 59.055 | 72.835 | ||

| HWK160 | 5.11– 6.29 | 12875 | 59.055 | 72.835 | ||

| HWK200 | 6.29 – 7.87 | 13940 | 59.055 | 72.835 | ||

| CABLE SUPPORT GRIPS | ||||||

|---|---|---|---|---|---|---|

| WHIPSOCKS | ||||||

| Part No | Cable Diameter | Safe Working Load (SF:3) | Mesh length | Total length | ||

| mm | Kg | mm | in mm | |||

| HWK10 | 06 – 10 | 240 | 600 | 800 | ||

| HWK15 | 10 – 15 | 600 | 600 | 800 | ||

| HWK20 | 15 – 20 | 600 | 600 | 800 | ||

| HWK25 | 20 – 25 | 750 | 600 | 800 | ||

| HWK30 | 25 – 30 | 900 | 1000 | 1200 | ||

| HWK40 | 30 – 40 | 1440 | 1250 | 1450 | ||

| HWK50 | 40 – 50 | 1650 | 1250 | 1450 | ||

| HWK60 | 50 – 60 | 3890 | 1500 | 1800 | ||

| HWK70 | 60 – 70 | 3890 | 1500 | 1800 | ||

| HWK90 | 70 – 90 | 4375 | 1500 | 1800 | ||

| HWK110 | 90 – 110 | 4860 | 1500 | 1850 | ||

| HWK130 | 110 – 130 | 5350 | 1500 | 1850 | ||

| HWK160 | 130 – 160 | 5840 | 1500 | 1850 | ||

| HWK200 | 160 – 200 | 6300 | 1500 | 1850 | ||

For further details click here to download our Brochure or Contact us.